We’re not just another vendor. We’re a creative partner.

Guided by well-honed methodologies, our teams work together for successful outcomes on every project.

Design Development

- Pre-planning

- Financial Modeling

- Team Set-up

- Refinement & Detail Drawings

Client Services

For every project milestone in front of you, we put a strong Client Services team beside you. As your creative partner, our highly collaborative team will work with you each step of the way – continuously identifying and tracking critical milestones, maintaining consistent communication, proactively addressing issues of schedule and budget, and ultimately making sure your vision comes to life.

Project Management

Our approach is highly collaborative, working with you each step of the way to craft every individual exhibit to your vision and create the best project outcomes. We are very hands-on and involved managers. Working through the steps outlined below, we continuously identify and track critical milestones, maintain consistent communication among all parties, and regularly address issues of schedule and budget to keep your project on track.

Engineering Team

Our engineers have the ability to combine traditional engineering techniques with modern technology to propel design projects beyond perceived limitations. Their in-depth knowledge backed by years of experience allows them to create one-of-a-kind ideas and design solutions that ensure originality and quality.

Engineering

- Feasibility Studies

- Interactive Experiences

- Mock-Ups

- Product Development & CAD

- Sampling

- Value Engineering

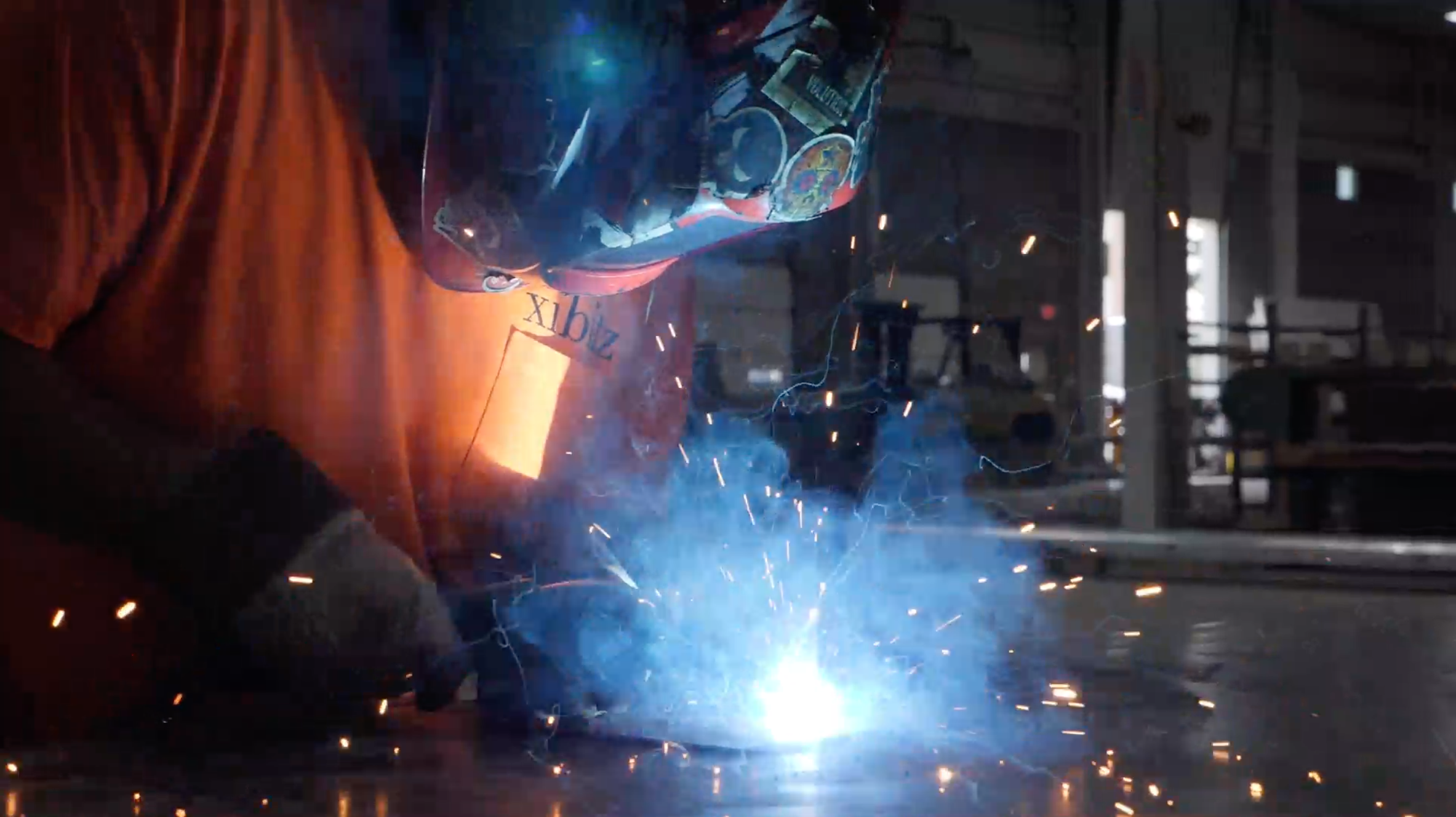

Fabrication Team

The quality of our fabrication is driven by lead fabricators who take charge. These leads work with project managers on each exhibit element to plan production sequences, identify materials to be purchased, and determine the fabrication methods to be used.

Fabrication

- Audio/Visual & Experiential

- Carpentry

- Electrical Assemblies

- Etching & Sandblasting

- Finishing

- Graphics Production

- High-quality Finishing

- Lighting Integration

- Metal Fabrication

- Welding

Implementation + Installation Team

Our staff has unparalleled experience at on-site installations. We “set up shop” wherever we go, bringing the tooling needed to complete the project. We will provide an installation lead knowledgeable about the entire project who will be the on-site “go-to” person for you during this crucial phase.

Installation

- Efficient & Clean Mobilization

- International Capabilities

- Maintenance Manuals

- on-site Training

- Refresh & Remediation

- Safety Management